Starting a poultry feed mill is an ambitious venture that can prove highly profitable if executed correctly. However, it requires careful planning, research, and a clear understanding of the industry’s demands and challenges. The first step in establishing a successful feed mill is to thoroughly assess the market needs and potential demand in the target area. Understanding the local poultry farming practices, the types of poultry being raised, and existing competitors can help determine the scope and scale of the operation. Conducting a detailed market analysis allows prospective entrepreneurs to identify gaps in the supply chain, specific customer preferences, and potential opportunities for niche markets such as organic or specialized feeds. Without this foundational knowledge, the business risks facing oversupply, under-demand, or misaligned product offerings.

Regulatory Requirements and Licensing

Before setting up a poultry feed mill, it is essential to familiarize oneself with the legal and regulatory landscape governing feed production in the region. Different countries and states have specific laws concerning the manufacturing, labeling, and sale of animal feed. Acquiring the necessary licenses, permits, and certifications is a critical step to ensure legal compliance and avoid potential penalties or shutdowns. These requirements often include health and safety standards, environmental regulations, and adherence to quality control protocols. Additionally, understanding the standards set by veterinary and agricultural authorities can help ensure that the feed produced is safe and nutritious for poultry. Engaging with local authorities and industry associations can facilitate a smoother licensing process and provide valuable guidance on compliance issues.

Equipment and Technology Needs

The choice of equipment and technology is fundamental to establishing an efficient and productive feed mill. Depending on the scale of the operation, the initial investment can vary significantly. Key equipment includes raw material handling systems, grinding machines, mixing units, pelletizers, and packaging machinery. Modern feed mills also incorporate automation and control systems that enhance precision, reduce labor costs, and improve product consistency. It is important to select durable, high-quality machinery suited to the size of the business and the types of feed to be produced. Additionally, investing in technology that allows for easy monitoring and quality control can improve efficiency and product reliability. Proper equipment planning not only affects production capacity but also impacts operational costs, maintenance requirements, and the overall lifespan of the mill.

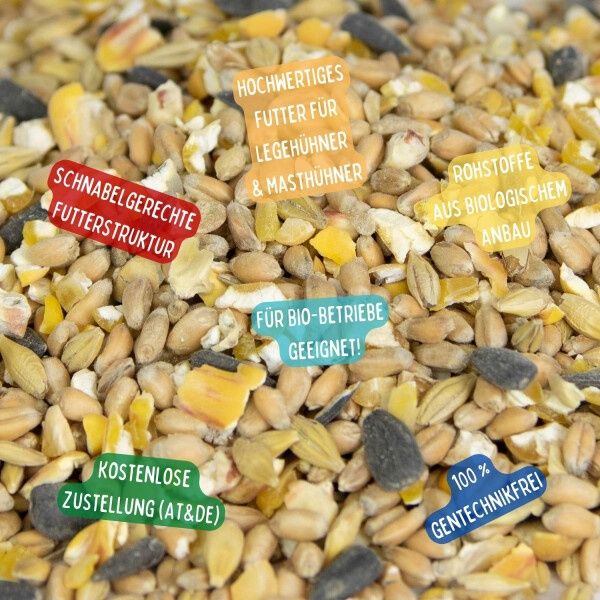

Raw Material Sourcing and Ingredient Quality

A crucial factor in the success of a poultry feed mill is sourcing high-quality raw materials. The main ingredients typically include grains like maize and soybean, along with vitamins, minerals, and additives as per formulation requirements. Building relationships with reliable suppliers who can provide consistent, quality raw materials is essential to maintain the integrity of the final product. Importantly, raw material quality directly impacts the nutritional value of the feed, bird health, and overall farm productivity. It is wise to implement strict quality control measures and regularly test incoming ingredients to ensure they meet safety and nutritional standards. Additionally, considering local sourcing options can reduce transportation costs and support regional agriculture, contributing to a more sustainable supply chain.

Production Capacity and Financial Planning

Determining the appropriate production capacity is a critical aspect of planning a poultry feed mill. Factors such as the size of the local poultry industry, target market segments, and available capital influence this decision. Starting with a capacity that matches projected demand can help avoid overextending resources or underutilizing equipment. Alongside capacity planning, comprehensive financial analysis is necessary to estimate startup costs, including land, machinery, raw materials, labor, and licensing fees. Developing a detailed business plan with clear financial projections helps identify funding needs, potential return on investment, and cash flow management strategies. It is also prudent to include contingency plans for fluctuations in raw material prices, market demand, or unforeseen operational expenses to ensure long-term sustainability.

Environmental and Workforce Considerations

An often overlooked aspect before starting a feed mill is understanding the environmental impact and workforce management. Feed production involves handling dust, waste, and chemical additives, which necessitate implementing proper waste disposal and pollution control measures. Ensuring compliance with environmental regulations not only prevents legal issues but also promotes community goodwill. On the workforce side, hiring skilled workers with experience in feed manufacturing, quality control, and machinery operation is vital for maintaining high standards. Providing proper training and safety measures protects employees and improves productivity. Additionally, establishing efficient logistics for raw material delivery and finished product distribution is essential for smooth operations. A well-planned environmental strategy combined with a competent workforce can significantly enhance the reputation and profitability of the feed mill.

Conclusion: Planning for Success

Embarking on the journey to start a Geflügelfutter mill requires meticulous planning, thorough knowledge, and strategic decision-making. From understanding market needs and complying with regulations to choosing the right equipment, sourcing quality ingredients, and managing finances, each step plays a vital role in establishing a successful operation. Paying careful attention to environmental sustainability and workforce management can further set the foundation for long-term success. By considering these factors carefully before launching, entrepreneurs can minimize risks, optimize operational efficiency, and position their feed mill as a reliable supplier in the poultry industry. With diligent preparation and a focus on quality and sustainability, starting a poultry feed mill can become a lucrative and rewarding venture.