In the intricate world of ink manufacturing, where microns matter and consistency is king, the machinery used cannot be a compromise. Producing inks for high-resolution printing, flexible packaging, or industrial coding demands an almost surgical level of control over every element of the process. Polyc Machine has engineered its ink production machine systems not as generic mixers, but as integrated technological platforms where each component plays a critical, specialized role in achieving precision output. For manufacturers aiming to produce flawless batches every single time, understanding these essential components reveals why a Polyc system is more than equipment—it’s a guarantee of reliability. From the initial feed to the final micron-level refinement, every part is purpose-built to eliminate variables and deliver exacting quality.

High-Shear Disperser with Intelligent Torque Control

The journey to precision begins with the foundational step of breaking down and wetting pigments, and for this, a standard agitator is wholly insufficient. The heart of the Polyc system is its advanced high-shear disperser. This is not merely a powerful motor with a spinning blade; it’s an intelligently controlled dispersion unit. Featuring a variable frequency drive and real-time torque monitoring, the system adapts its energy input to the specific rheology of the batch. As the pigment agglomerates break down, the viscosity changes, and the disperser automatically adjusts its speed and power to maintain optimal shear without over-processing or generating excess heat. This intelligent component ensures that the critical first stage of production achieves perfect particle wetting and color development consistently, forming the non-negotiable base for all that follows.

Precision Liquid and Powder Dosing Systems

Accuracy in batching is where precision is either secured or lost at the outset. Polyc machines incorporate meticulously calibrated dosing systems for both liquids and powders. For liquids like resins, solvents, and additives, high-accuracy mass flow meters or precision piston pumps deliver ingredients directly from bulk storage to the process vessel. For powders, automated vacuum conveying systems transport pigments from sealed containers to integrated weigh hoppers mounted on ultra-precise load cells. These components work in concert with the control software, which records every gram added against the digital recipe. This eliminates the guesswork and potential for human error inherent in manual scooping or drum tipping, guaranteeing that the chemical foundation of every ink batch is mathematically exact to the formula.

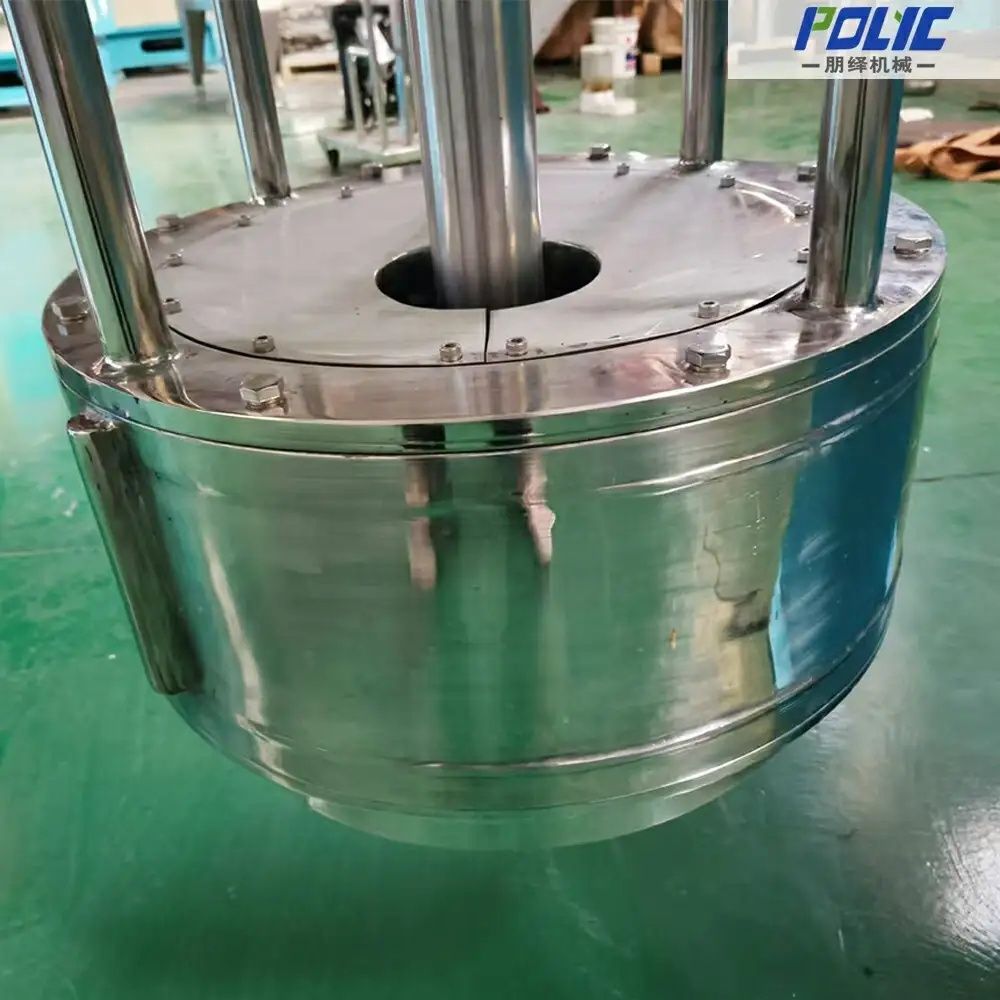

Closed-Circuit Circulation Mill for Ultimate Refinement

After pre-dispersion, many premium inks require further refinement to reach the sub-micron particle size necessary for smooth application and intense color strength. This is the task of the circulation bead mill, a cornerstone component in Polyc’s precision arsenal. In this closed-loop system, the pre-mix is pumped through a chamber filled with fine grinding media. The intense agitation within the mill fractures particles to a uniform, minuscule size. The closed-circuit design is key: the ink recirculates until an in-line fineness of grind gauge confirms the target particle distribution has been achieved. This component provides a level of control and repeatability impossible with open or single-pass milling, ensuring the final product’s texture and performance are precisely dialed in, batch after batch.

In-Line Rheology and Viscosity Monitoring

Precision is not a set-and-forget proposition; it requires constant vigilance. Polyc systems integrate sophisticated in-line monitoring components to act as the "eyes and ears" of the process. A critical example is the in-line viscometer, which provides a continuous, real-time readout of the ink's viscosity as it circulates. This data is fed directly back to the control system. If the viscosity deviates from the narrow target window, the system can be programmed to automatically make a micro-adjustment, such as adding a precise amount of solvent. This closed-loop feedback control compensates for minor batch variations in raw materials or ambient conditions, ensuring the final product’s flow characteristics are perfect for its intended application, whether it’s a high-speed web press or a precision inkjet head.

Programmable Logic Control (PLC) with Recipe Management

The component that orchestrates all the others is the centralized Programmable Logic Controller. This is the digital brain of the operation. Polyc’s PLC is not a simple timer; it is a powerful industrial computer loaded with specialized software. Its core function is a comprehensive recipe management system where hundreds of formulations are stored with exact parameters for every component’s operation—dispersion speeds, milling times, temperature limits, and ingredient quantities. An operator simply selects "Ink Formula #207," and the PLC executes the entire sequence flawlessly. This component transforms complex chemical engineering into a repeatable, automated process, removing operator discretion as a variable and locking in procedural precision from start to finish.

Temperature-Controlled Vessel and Jacketed Piping

The chemical reactions and physical processes in ink manufacturing are highly sensitive to thermal changes. Uncontrolled heat can alter viscosity, affect dispersion, or even damage sensitive ingredients. To nullify this variable, Polyc machines feature precisely engineered temperature-control components. The main process vessels and critical piping are fully jacketed, allowing a thermal fluid (heated or chilled) to circulate around them. This is managed by the PLC in conjunction with in-line temperature probes, maintaining the batch within a tight thermal band throughout its entire cycle. By providing this stable thermal environment, these components ensure that the precision achieved in formulation and mechanical processing is not undone by something as fundamental as friction-induced heat or a warm factory floor.

Together, these components form a synergistic ecosystem dedicated to one outcome: uncompromising precision. In an industry where a single imperfect batch can shut down a client’s printing press or ruin a million packaging labels, this level of engineered reliability is not a luxury—it is the essential foundation of a reputable and competitive ink manufacturing business. Polyc’s machine provides that foundation, component by critical component.